The smart Trick of Premier Aluminum Llc That Nobody is Talking About

The smart Trick of Premier Aluminum Llc That Nobody is Talking About

Blog Article

The Best Guide To Premier Aluminum Llc

Table of ContentsPremier Aluminum Llc - QuestionsSome Known Incorrect Statements About Premier Aluminum Llc Our Premier Aluminum Llc StatementsTop Guidelines Of Premier Aluminum Llc

(https://www.slideshare.net/garymartin53403)Typically, a buyer's main obligation was to locate qualified and receptive providers. In many cases, purchasers assumed that any provider willing to contractually satisfy the acquisition demand was certified. Using low cost and unqualified providers can create top quality issues, and squandered time and money in the long run. To assist you with the process, below are some points to take into consideration when selecting the right steel spreading supplier.

For instance, a business that just makes use of the financial investment casting process will attempt to sell you on why that procedure is best for your application. However what if utilizing the sand spreading procedure is best for you and your needs? Instead, try to find a supplier that uses an array of casting processes so the very best alternative for YOU is chosen

If collaborating with a solitary source for all of your casting requires is essential to you, the vendor needs to be varied in its abilities. When incorporated with other incorporated abilities, this can aid streamline and press the supply base. When choosing the appropriate spreading supplier, mindful factor to consider should be provided to top quality, service, and cost.

Top Guidelines Of Premier Aluminum Llc

Buyers significantly pick casting providers who have machining abilities. This can stay clear of conflict if issues are uncovered during machining. If a third celebration is machining, it may lead to "finger-pointing" concerning who is at mistake. Is it a spreading concern or a machining concern? If the spreading provider finds a concern during machining, the trouble is resolved quicker with no conflict over whose fault it is.

Trouble or no, incorporated machining simplifies the supply chain and decreases managing time and shipping cost prior to the item makes it to the client. What do you need from your spreading supplier? Are you looking for somebody to just provide a steel element to your doorstep or do you need more? As an example, if you do not have in-house metallurgy knowledge, verify that the supplier can provide advice in selecting the appropriate alloy based on your particular application - Foundries in Wisconsin.

Others will go beyond the letter of the PO to assist you save money and time. Do you have demands for both ferrous and non-ferrous alloys? Some foundries are limited or specialized. Make sure the distributor can fulfill all your material or alloy needs to get rid of the need for multiple distributors.

A Biased View of Premier Aluminum Llc

Study the vendor's site. Talk to a sales representative or organization partner.

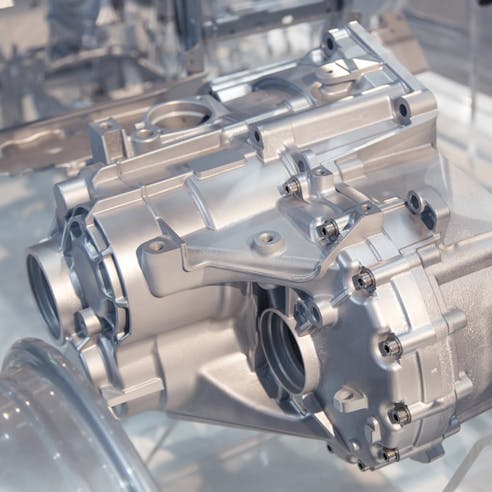

Aluminum is additionally light-weight and has great corrosion resistance, making it ideal for applications where weight and resilience are necessary variables. Additionally, light weight aluminum casting is a cost-effective method of production, as it needs less power and resources than other methods. Iron spreading, on the other hand, includes pouring molten iron right into a mold and mildew to produce a wanted shape.

3 Simple Techniques For Premier Aluminum Llc

Iron casting is also able to withstand high temperatures, making it ideal for use in applications such as engine components and industrial equipment. Nonetheless, iron spreading can be much more pricey than aluminum casting YOURURL.com due to the greater expense of basic materials and the energy required to melt the iron. When making a decision in between light weight aluminum casting and iron spreading, it is necessary to take into consideration the specific demands of the application.

In verdict, both aluminum spreading and iron casting have their own distinct benefits and disadvantages. There are 3 sub-processes that drop under the classification of die spreading: gravity pass away spreading (or long-term mold and mildew casting), low-pressure die casting and high-pressure die casting. To get to the finished item, there are three key alloys used as die casting product to pick from: zinc, light weight aluminum and magnesium. Report this page